naoki

Well-Known Member

I'm not sure if this post belongs in "culture" section, but the light source is an important aspect of our slipper culture for us who rely on artificial light. So I thought that some of you might be interested in this.

I was curious about those Chip-on-board (COB) style LED from China. So I saved up my milk allowance and invested $15 to play with this toy.

Here is everything needed:

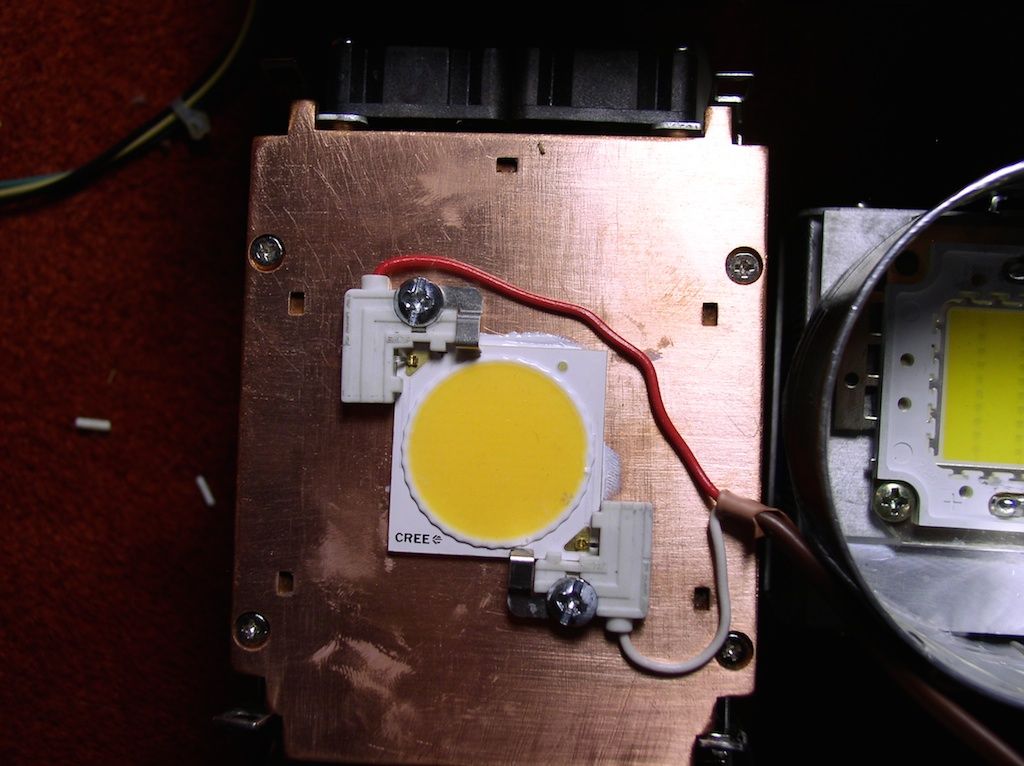

From right, AC/DC adapter to drive the cooling fan. Some cell phone charger is probably good enough. I wouldn't use those big, super-old ones which aren't efficient. Reflector is made out of tomato sauce can. I put the foil tape (usually used for ducting) inside to make it silver (instead of gold). 30W diode is attached to an old CPU heatsink after putting thin layer of thermal grease. Then at the left, you can see 30W constant current driver (900mA, forward voltage 30-34V DC). The green bottle is the case for the driver. The "listed" spec of the LED is:

30W Warm White

Forward Voltage (VF): DC 33-35V

Forward current (IF): 1050MA

Output Lumens: 2500-3500LM

beam angle: 140 degree

The construction is super easy. 2 wires of the driver need to be connected to AC plug. Then 2 other wires need to be soldered to + and - of diodes. You should solder before attaching it to the heatsink.

Cost:

I got a 30W emitter + constant current driver from ebay (about $15 including shipping). Additionally, you need a AC/DC converter, an old CPU heatsink+fan, and cables with AC plug. But it's likely that you can find these for free or very cheaply. I used a tomato sauce can (+ foil tape) for a reflector. So the total cost for me is $15. It is almost as cheap as 23W CFL + 8.5" clip lamp.

Comparison against CFL:

Both CFL (left) and LED (right) are at the same hight from the floor (about 10"). The photo gives you an idea of the beam spread. Note that for this photo, I didn't have the reflector attached to LED. Reflector makes the lighted area slightly smaller.

Also, both CFL and LED are "warm" white, and they give relatively similar perceived "color". But most florescent lights have only a few (3-5) sharp peaks in the emission spectrum and white LED has a more continuous spectrum.

CFL is Lite Source LT-23SP, 23W 2700K with cheap 8.5" Clamp Light (Commercial Electric 277-894 from Home Depot). Actual measured energy consumption is 23W.

30W LED consumes 30.8W. The cooling fan driven at 6V consumes 2.6W (6W @ 12V, 1.8W @3V, and 3V is probably good enough, though). So total of 33.4W.

Measurement (with Gossen Ultra Pro light meter, 12" from the tip of the light source):

CFL: 300 fc

LED: 550 fc (520 fc without tin can reflector)

CFL: 300fc/23W = 13fc/W

LED: 550/33.4W = 15.6fc/W

So LED provides about 20% more light per watt.

Light spread

To roughly understand the beam spread pattern, I measured right below the light, 6" off-center and 12" off-center. Light is 12" above the measuring plain.

CFL: 100% @ center, 53.3% @ 6" off-center, 23.0% @ 12" off-center

LED: 100% @ center, 65.5% @ 6" off-center, 32.7% @ 12" off-center

So LED has a wider usable spread in this case. In other words, actual advantage of LED is greater than 20%.

misc:

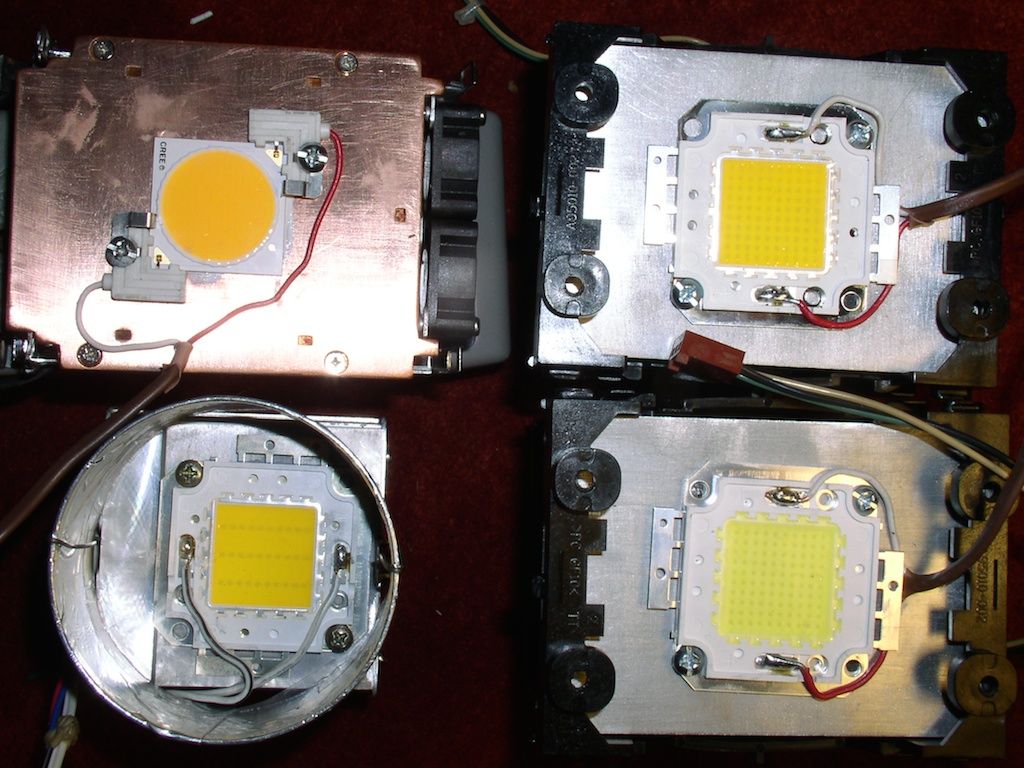

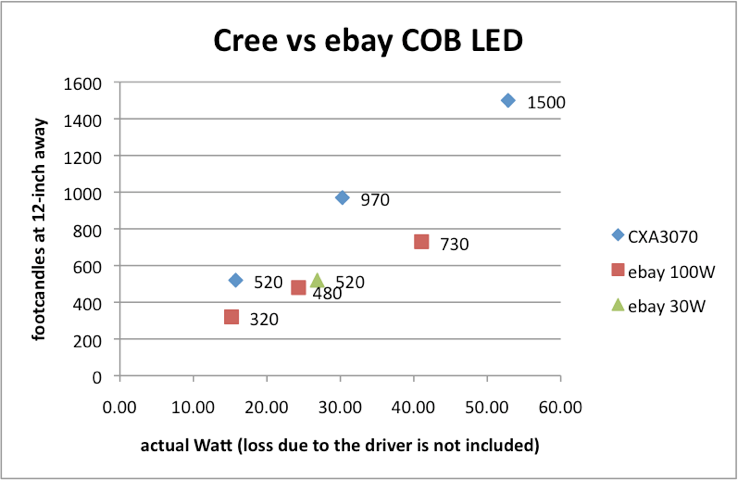

This cheap LED is probably crappy (in efficiency) compared to better COB LEDs such as Bridelux Vero or Cree XLamp CXA. I would say that the output of this cheap ebay LED is better than I expected, and it is super cheap and usable for orchids. We'll see how long it will last. In a long term, you'll probably save money with Vero or CXA than the less efficient, cheap LED even though the initial cost is higher. However, the white LED technology seems to keep changing rapidly, so low initial cost could be a good thing.

If you are not into DIY, you can find preassembled LED flood light (e.g. $30 for 30W), which uses a similar LED. You may need to attach AC plug, but you don't need to solder, and you get water-proofed case and reflector. It seems like a pretty good deal compared to T5HO. But I'm not sure how effectively the heat is dissipated, and how long they will last.

Here is a link to something similar (the link will die eventually):

30W LED Warm Cool White High Power 3300LM Lamp Chip 30W Power Driver 85 265V | eBay

100W LED Warm Cool White High Power Lamp Chip 100W Power Driver AC 85 265V | eBay

LED Flood light example:

10W 20W 50W 100W 200W LED Warm AC or DC White RGB Spotlight Flood Light Garden | eBay

I'm linking to the ebay seller, whom I had a good luck with. I received a partially broken LED at first, but they immediately sent me another working one without any troubles.

I was curious about those Chip-on-board (COB) style LED from China. So I saved up my milk allowance and invested $15 to play with this toy.

Here is everything needed:

From right, AC/DC adapter to drive the cooling fan. Some cell phone charger is probably good enough. I wouldn't use those big, super-old ones which aren't efficient. Reflector is made out of tomato sauce can. I put the foil tape (usually used for ducting) inside to make it silver (instead of gold). 30W diode is attached to an old CPU heatsink after putting thin layer of thermal grease. Then at the left, you can see 30W constant current driver (900mA, forward voltage 30-34V DC). The green bottle is the case for the driver. The "listed" spec of the LED is:

30W Warm White

Forward Voltage (VF): DC 33-35V

Forward current (IF): 1050MA

Output Lumens: 2500-3500LM

beam angle: 140 degree

The construction is super easy. 2 wires of the driver need to be connected to AC plug. Then 2 other wires need to be soldered to + and - of diodes. You should solder before attaching it to the heatsink.

Cost:

I got a 30W emitter + constant current driver from ebay (about $15 including shipping). Additionally, you need a AC/DC converter, an old CPU heatsink+fan, and cables with AC plug. But it's likely that you can find these for free or very cheaply. I used a tomato sauce can (+ foil tape) for a reflector. So the total cost for me is $15. It is almost as cheap as 23W CFL + 8.5" clip lamp.

Comparison against CFL:

Both CFL (left) and LED (right) are at the same hight from the floor (about 10"). The photo gives you an idea of the beam spread. Note that for this photo, I didn't have the reflector attached to LED. Reflector makes the lighted area slightly smaller.

Also, both CFL and LED are "warm" white, and they give relatively similar perceived "color". But most florescent lights have only a few (3-5) sharp peaks in the emission spectrum and white LED has a more continuous spectrum.

CFL is Lite Source LT-23SP, 23W 2700K with cheap 8.5" Clamp Light (Commercial Electric 277-894 from Home Depot). Actual measured energy consumption is 23W.

30W LED consumes 30.8W. The cooling fan driven at 6V consumes 2.6W (6W @ 12V, 1.8W @3V, and 3V is probably good enough, though). So total of 33.4W.

Measurement (with Gossen Ultra Pro light meter, 12" from the tip of the light source):

CFL: 300 fc

LED: 550 fc (520 fc without tin can reflector)

CFL: 300fc/23W = 13fc/W

LED: 550/33.4W = 15.6fc/W

So LED provides about 20% more light per watt.

Light spread

To roughly understand the beam spread pattern, I measured right below the light, 6" off-center and 12" off-center. Light is 12" above the measuring plain.

CFL: 100% @ center, 53.3% @ 6" off-center, 23.0% @ 12" off-center

LED: 100% @ center, 65.5% @ 6" off-center, 32.7% @ 12" off-center

So LED has a wider usable spread in this case. In other words, actual advantage of LED is greater than 20%.

misc:

This cheap LED is probably crappy (in efficiency) compared to better COB LEDs such as Bridelux Vero or Cree XLamp CXA. I would say that the output of this cheap ebay LED is better than I expected, and it is super cheap and usable for orchids. We'll see how long it will last. In a long term, you'll probably save money with Vero or CXA than the less efficient, cheap LED even though the initial cost is higher. However, the white LED technology seems to keep changing rapidly, so low initial cost could be a good thing.

If you are not into DIY, you can find preassembled LED flood light (e.g. $30 for 30W), which uses a similar LED. You may need to attach AC plug, but you don't need to solder, and you get water-proofed case and reflector. It seems like a pretty good deal compared to T5HO. But I'm not sure how effectively the heat is dissipated, and how long they will last.

Here is a link to something similar (the link will die eventually):

30W LED Warm Cool White High Power 3300LM Lamp Chip 30W Power Driver 85 265V | eBay

100W LED Warm Cool White High Power Lamp Chip 100W Power Driver AC 85 265V | eBay

LED Flood light example:

10W 20W 50W 100W 200W LED Warm AC or DC White RGB Spotlight Flood Light Garden | eBay

I'm linking to the ebay seller, whom I had a good luck with. I received a partially broken LED at first, but they immediately sent me another working one without any troubles.